New Industrial Style with a Better Grip

The Pacific SF Fittings are forged with Industrial Style Helical Knurling Designed Rotators made with high-quality brass and treated with a special surface finishing, creating a new look with fantastic aesthetics and providing a more ergonomic grip while installing.

Install Freely without Worry

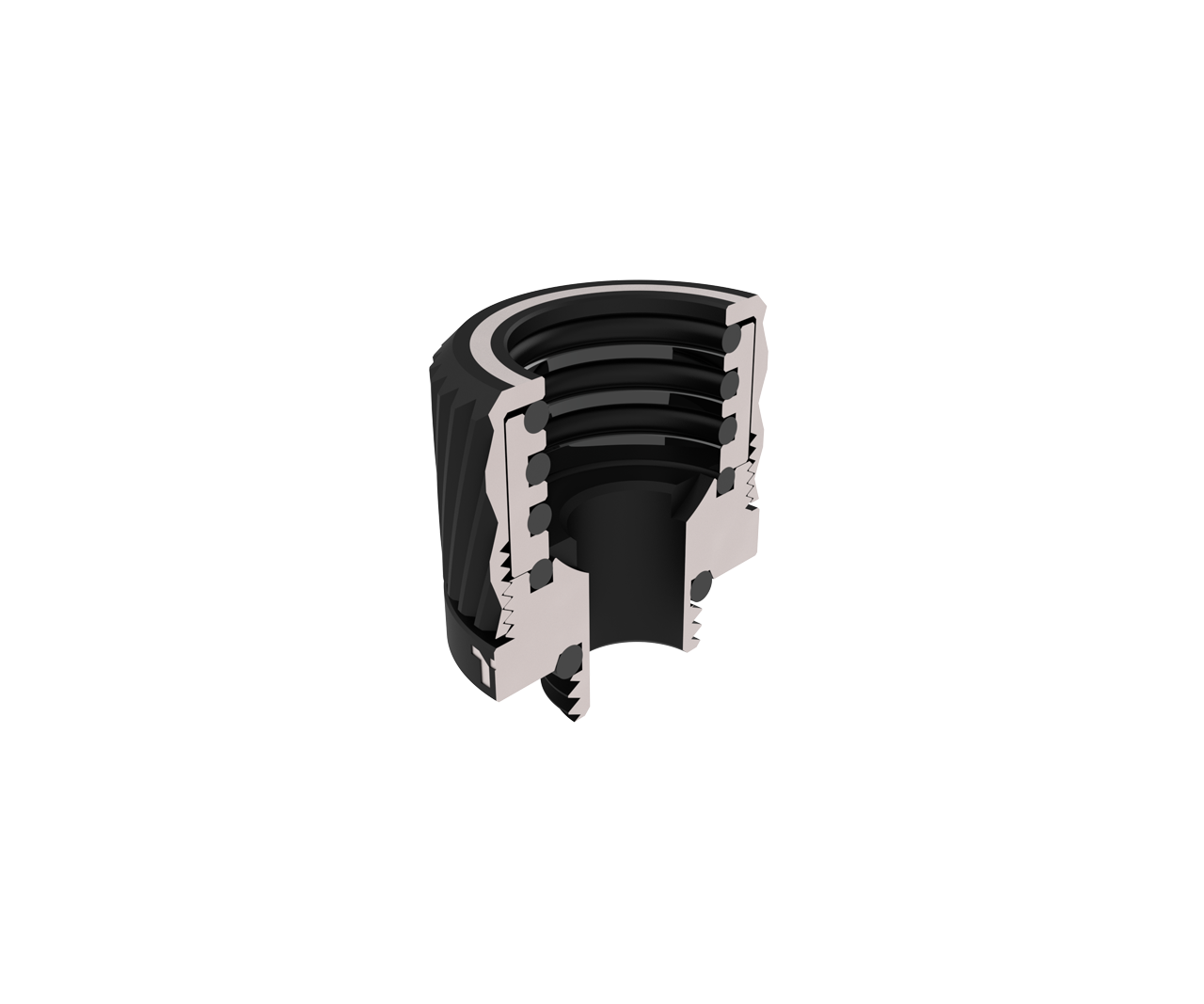

Pacific SF Hard Tube 16mm OD Compression fittings can be used with PETG, Acrylic, and Glass tubing, which is 16mm in outer diameter (OD) and paired with G1/4 screw threads. They are designed to work in tight spaces without compromising the compression seal or impacting the coolant flow. They also feature four O-Rings to provide a more secure seal and reliable performance.

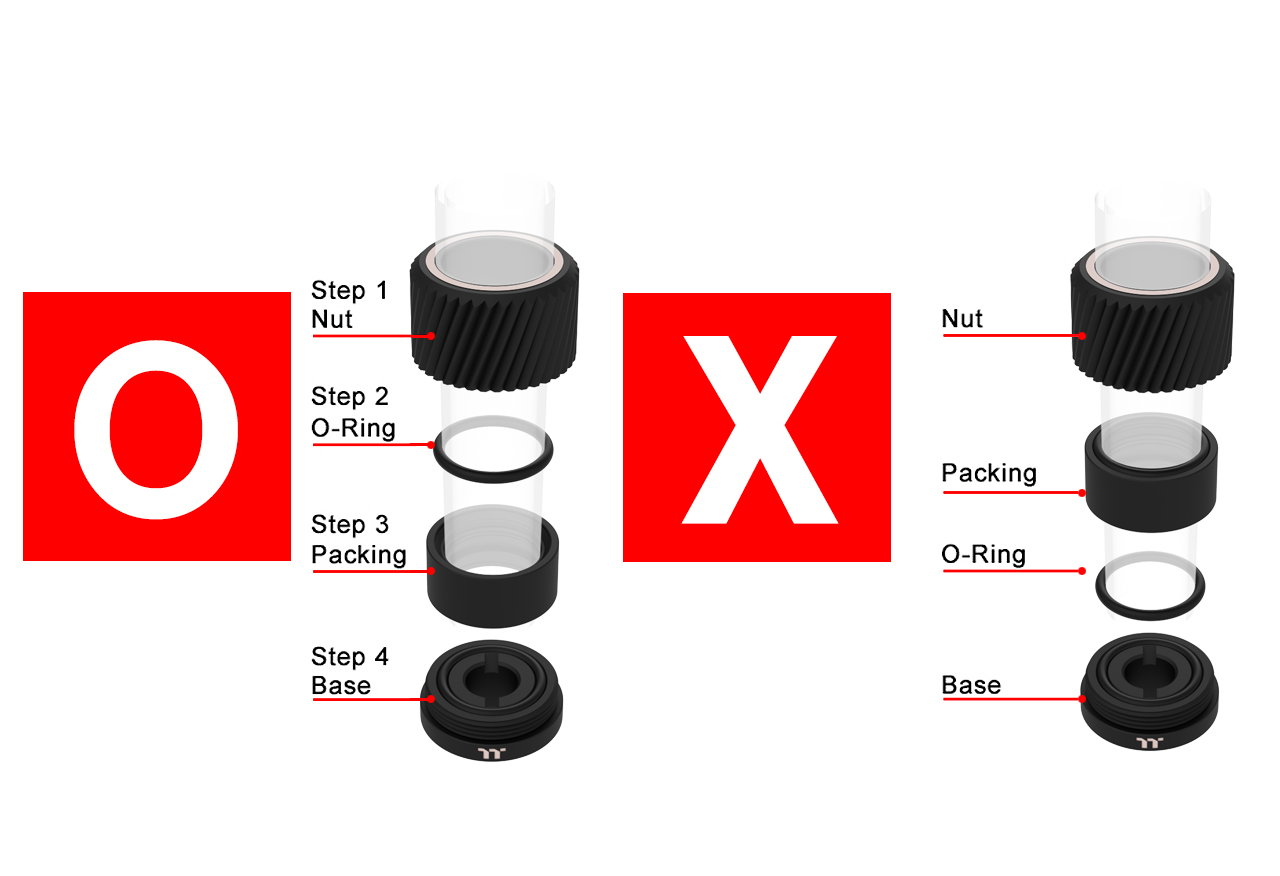

Thermaltake Pacific SF Fittings Installation Guide

Step 1. Slide the compression nut over the tube

Step 2. Install the O-Ring

Step 3. Install the packing

Step 4. Install the fitting base on your components

Step 5. Tighten the compression nut

Caution: The O-Ring and the packing with a groove on the inside diameter must always be installed towards the top of the compression nut.

Cautions

Thermaltake recommends the following steps to be taken before using the Pacific series radiators and water blocks:

- To ensure a clean loop, flush and rinse your radiators and water blocks with distilled water prior to use.

- Do not use tap water or distilled water as your coolant, it may harm your loop and reduce performance.

- It is strongly recommended to use market-proven pre-mix coolant, such as Thermaltake Coolant 1000, which offers great performance while protecting the entire liquid loop from corrosion.

- Before storing your water cooling components, please clean, rinse, and dry. This will ensure a longer lifespan for your components.

Thermaltake recommends the following steps to be taken after completing your water loop setup:

- It is strongly recommended to use market-proven pre-mix coolant, such as Thermaltake Coolant 1000, which offers great performance while preventing corrosion in the entire cooling system (copper, brass, nickel, aluminum, and steel).

- Fill the reservoir with coolant and cycle the power on and off several times while the pump pushes the coolant into the loop.

- DO NOT let the pump run dry. If no liquid is entering the pump, turn off your power immediately.

- Fill the reservoir to the top to prevent air from entering the pump.

- If necessary, tilt the system slightly from side to side to bleed the air out of the loop.

- Place paper towels under fittings and joining points to test for leaks.

- Run the loop with the fill port open for about 24 hours to completely bleed the air out of the loop.

- Before starting, flush out your system properly to prevent any coolant or unwanted particles from sticking to your tubes, radiators, and other cooling components.

- Coolant might fade over time.

| P/N | CL-W389-CA16MK-A |

|---|---|

| Dimensions | ∮27 x 25 (H) (mm) |

| Weight | 53 g |

| MATERIAL | CU + AL |

| Note | Connector To Tube |

| Applicable | OD : 16 mm |

| Screw thread | G 1/4 |